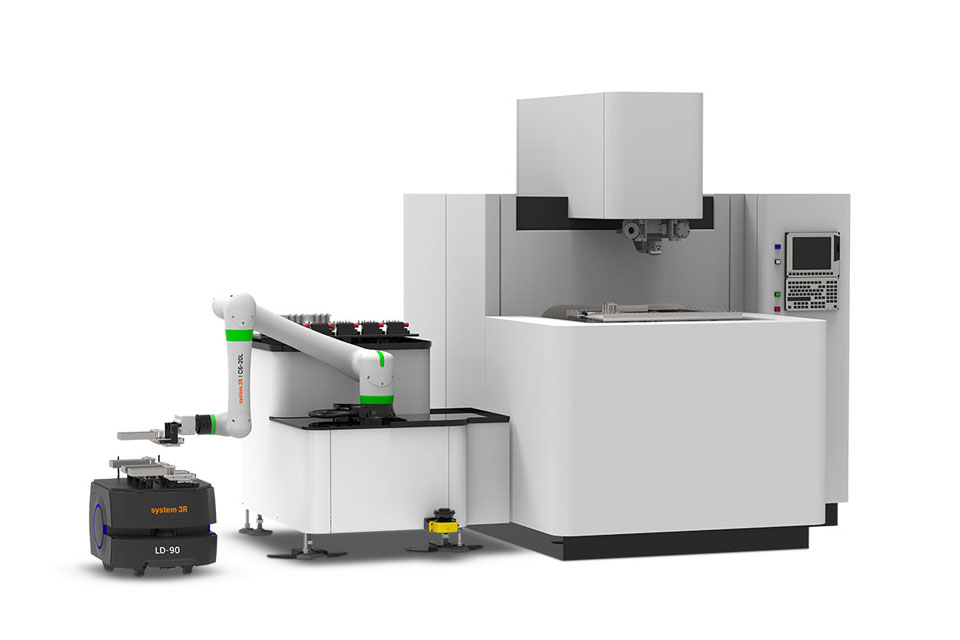

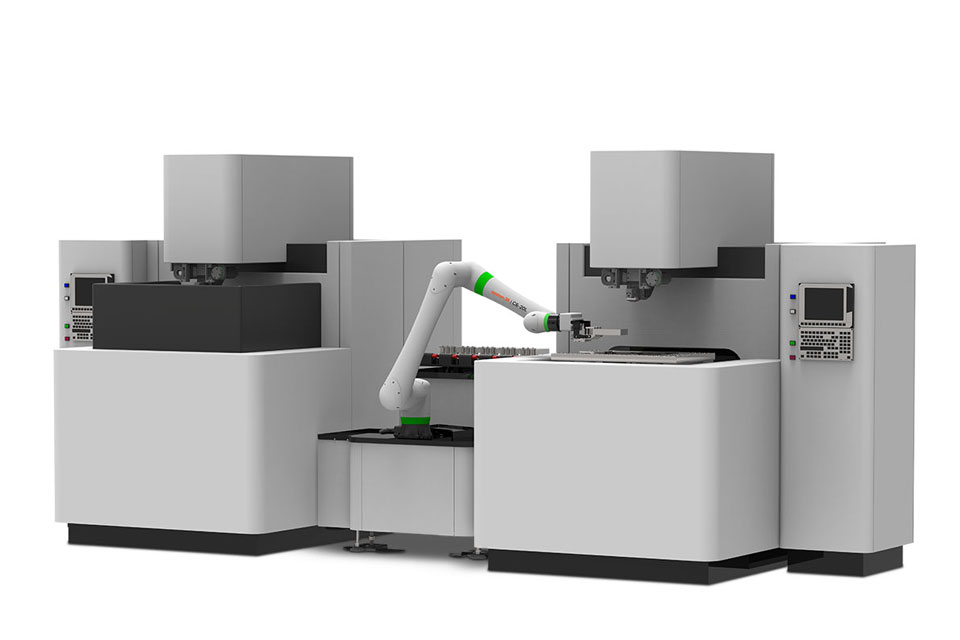

Collaborative Robot C6-20L

Smarter, safer, and more efficient — CRX cobots are built to optimize your production. Their lightweight design and energy-saving features reduce power use, while built-in safety ensures smooth, collaborative operation. Compact and reliable, they’re the ideal partner for boosting workflow and ROI.